Quality Control

Uses the best raw materials

EAM sources from reputable and reliable vendors globally to ensure quality raw materials are used for the production of EAM premium products. For the assurance of consistent quality products EAM builds accountability into every step of the process through having:- At least 2 trialed and approved suppliers for each of its raw material

- All incoming raw materials are tested and the verification of the material documented

- Integrated warehouse system where inventories are managed using FIFO

- Constantly evaluating alternate suppliers and vendors through rigorous testing

Fully Traceable Supply Chain

EAM asserts quality and security in its operation from acquisition of raw materials, through production and shipping to customers and distributors. Every process step is verified and documented so that the customer can be sure that EAM takes all effort in assuring product quality.Reliable and Trustworthy Laboratory

A reliable and trustworthy testing facility is the backbone of a high purity chemical business. Functions of the quality control laboratory are:- Characterisation of incoming raw materials to determine out-of-specification components which may affect product quality

- Intermediate testing to provide chemical feedback of processes for product consistency

- Scrutinise the quality of finished product and confirm specification of every solvent

- Issue quality control documents for customer’s assurance and in-house monitoring

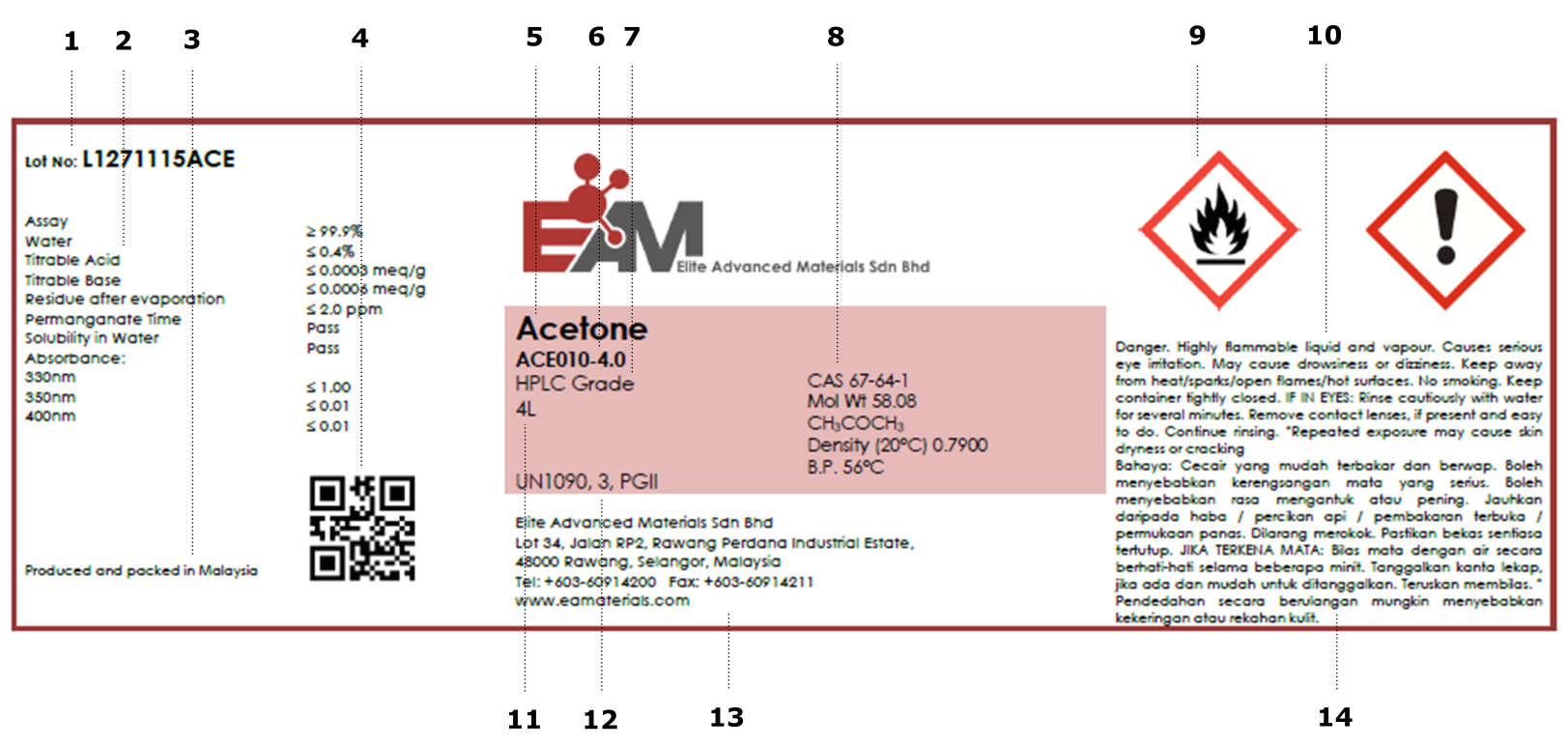

GHS labels and Safety Datasheet

EAM strives to comply with global standards as part of its commitment to achieve world-class quality system. All of EAM’s labels and safety documents are compliant with the Global harmonization System (GHS) of classification and labelling of chemicals.

1. LOT NUMBER

2. PRODUCT SPECIFICATIONS

3. PRODUCT ORIGIN

4. QR CODE

5. PRODUCT NAME

6. PRODUCT CODE

7. PRODUCT GRADE

2. PRODUCT SPECIFICATIONS

3. PRODUCT ORIGIN

4. QR CODE

5. PRODUCT NAME

6. PRODUCT CODE

7. PRODUCT GRADE

8. CAS NUMBER

9. GHS PICTOGRAM

10. SAFETY INFORMATION IN ENGLISH

11. PACKING INFORMATION

12. SHIPPING INFORMATION

13. EAM ADDRESS AND CONTACT

14. SAFETY INFORMATION IN BAHASA MALAYSIA

9. GHS PICTOGRAM

10. SAFETY INFORMATION IN ENGLISH

11. PACKING INFORMATION

12. SHIPPING INFORMATION

13. EAM ADDRESS AND CONTACT

14. SAFETY INFORMATION IN BAHASA MALAYSIA