EA Materials

ISO Certification

Category: EA Materials

ENVIRONMENTAL AND QUALITY MANAGEMENT POLICY

We are committed to continually improve on our activities, product, services, environmental and quality performance through leadership’s direction and commitment from all level, risk management and assessment periodic review & implementation in order to meet statutory and customer’s requirement. To uphold our commitment we shall :

To commit and comply with ISO 9001:2015 and ISO 14001:2015 through continual improvement of the effectiveness of Quality Management System and Environmental Management System respectively.

Prevent pollution and Depletion use of Water, Land and Air by:

- Improving wastes and chemical management systems.

- Improving monitoring and measurement of our management systems.

- Practice 3Rs (Reduce, Reuse, Recycle) to conserve natural resources.

Compliance to applicable statutory, customer’s product environmental and other legal requirements.

Ensure our products and services meet and exceed our customer’s expectation and quality requirement through continual improvement program.

We shall improve awareness among employees and vendors through communication and trainings.

Quality Control

Category: EA Materials

Uses the best raw materials

EAM sources from reputable and reliable vendors globally to ensure quality raw materials are used for the production of EAM premium products. For the assurance of consistent quality products EAM builds accountability into every step of the process through having:- At least 2 trialed and approved suppliers for each of its raw material

- All incoming raw materials are tested and the verification of the material documented

- Integrated warehouse system where inventories are managed using FIFO

- Constantly evaluating alternate suppliers and vendors through rigorous testing

Fully Traceable Supply Chain

EAM asserts quality and security in its operation from acquisition of raw materials, through production and shipping to customers and distributors. Every process step is verified and documented so that the customer can be sure that EAM takes all effort in assuring product quality.Reliable and Trustworthy Laboratory

A reliable and trustworthy testing facility is the backbone of a high purity chemical business. Functions of the quality control laboratory are:- Characterisation of incoming raw materials to determine out-of-specification components which may affect product quality

- Intermediate testing to provide chemical feedback of processes for product consistency

- Scrutinise the quality of finished product and confirm specification of every solvent

- Issue quality control documents for customer’s assurance and in-house monitoring

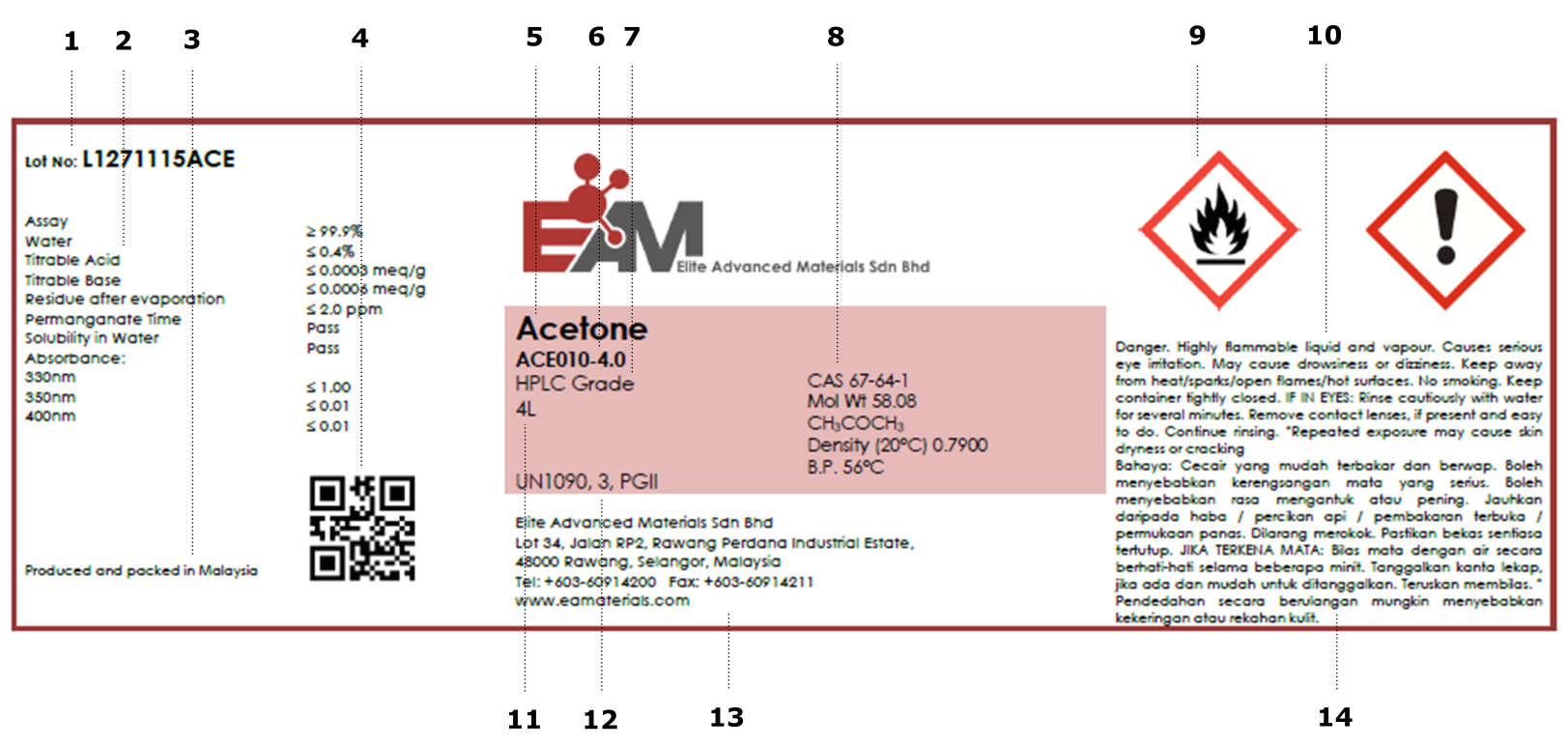

GHS labels and Safety Datasheet

EAM strives to comply with global standards as part of its commitment to achieve world-class quality system. All of EAM’s labels and safety documents are compliant with the Global harmonization System (GHS) of classification and labelling of chemicals.

1. LOT NUMBER

2. PRODUCT SPECIFICATIONS

3. PRODUCT ORIGIN

4. QR CODE

5. PRODUCT NAME

6. PRODUCT CODE

7. PRODUCT GRADE

2. PRODUCT SPECIFICATIONS

3. PRODUCT ORIGIN

4. QR CODE

5. PRODUCT NAME

6. PRODUCT CODE

7. PRODUCT GRADE

8. CAS NUMBER

9. GHS PICTOGRAM

10. SAFETY INFORMATION IN ENGLISH

11. PACKING INFORMATION

12. SHIPPING INFORMATION

13. EAM ADDRESS AND CONTACT

14. SAFETY INFORMATION IN BAHASA MALAYSIA

9. GHS PICTOGRAM

10. SAFETY INFORMATION IN ENGLISH

11. PACKING INFORMATION

12. SHIPPING INFORMATION

13. EAM ADDRESS AND CONTACT

14. SAFETY INFORMATION IN BAHASA MALAYSIA

Tamper-evident packaging

Tamper-evident packaging is a must to ensure the integrity of our products. Such packaging would allow our customers to recognise that products that have been tampered with. EAM uses tamper-evident cap for our 2.5L and 4L amber glass bottles. Once open, the tamper-evident band detaches from the cap to indicate that bottles are opened.Customized Blend

Category: EA Materials

In many cases, the solvents are used in a formulated blend. Most companies require chemists and production personnel to carry out the preparation of the formulation in-house. This takes up additional company resources which can be better used to increase productivity. Cross-contamination and inaccurate formulation mix may occur due to inadequate handling. EAM as a producer of high purity solvents is able to better support our clients with high quality, high purity customised solutions and start-of-the-art delivery system best suited to the company’s needs. EAM aims to relief customers’ resources by providing certified blend so that the laboratory and production can focus on high value workdone. We take confidentiality seriously and a mutual Non-Disclosure Agreement will be signed by both parties.

Contact Us

Category: EA Materials